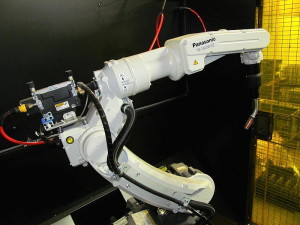

Hughes Parker Industries is pleased to announce the addition of a new Miller PerformArc 750ˆ robotic weld station.

This new robotic weld station dramatically increases HPI welding capacity and capabilities.

The PerformArc 750ˆ offers an extremely large work area, allowing HPI to robotically weld larger assemblies and there by complementing HPI’s existing robotic weld capabilities.